OEM Capabilities

When you’re looking to upgrade your ride, there are many options out there for you to choose from. When it comes to the hoses, you can go with standard rubber hoses, but those are bland, boring, and will likely deteriorate faster under high-pressure conditions. At Flex Technologies, we make high-quality silicone hoses at OEM standards to ensure they fit your system perfectly. Our flex hoses can be customized to your specifications to meet your needs. Our innovation and solutions-based design capabilities have earned us a reputation throughout the world for making reliable products you can trust to work under the conditions specified.

There are many reasons why custom-made hoses are a great option to choose over standard OEM hoses. By giving you the opportunity to specify exactly how you want your hoses and attachments to look and the features they come with, you’re able to maximize your system’s potential. Whether you’re using our hoses in a vehicle or another machine, you can determine where you want to improve performance and how, and Flex Technologies will produce it for you. No longer will you have to hope that you can find the massively produced part that covers your bases, since we’ll make exactly what you’re looking for on demand. With OEM products being produced on a massive scale, you’re forced to take what you can get. What that ends up being is plain black or gray rubber that can crack when under increased pressure. If you’re looking for hoses that stand up to pressure while providing you with the level of performance you want, custom silicone hoses certainly fit the bill. That makes them a great option for everything from motorsports to long-haul trucking, which require vehicles to be in peak operating condition and cannot afford setbacks from faulty equipment.

Beyond the performance aspect of Flex Technologies’ custom silicone hoses, you can also customize the appearance of the hoses to totally change the look of your engine block. Instead of boring and dull rubber hoses like OEM, you can add a beautiful splash of color to really make it pop. That makes our custom designs a great option for anyone who likes to show off their setup, whether it’s at a meet-up or a car show. That color will be even more impressive thanks to the shine of the silicone hose, which can work beautifully with a chrome engine block. The aesthetic customization doesn’t stop there. Flex Technologies also lets you customize the 3D shape of the hose. With nearly 2,000 design options, we’re sure you’ll find something that fits what you’re looking for, and if you don’t, we’ll design it for you.

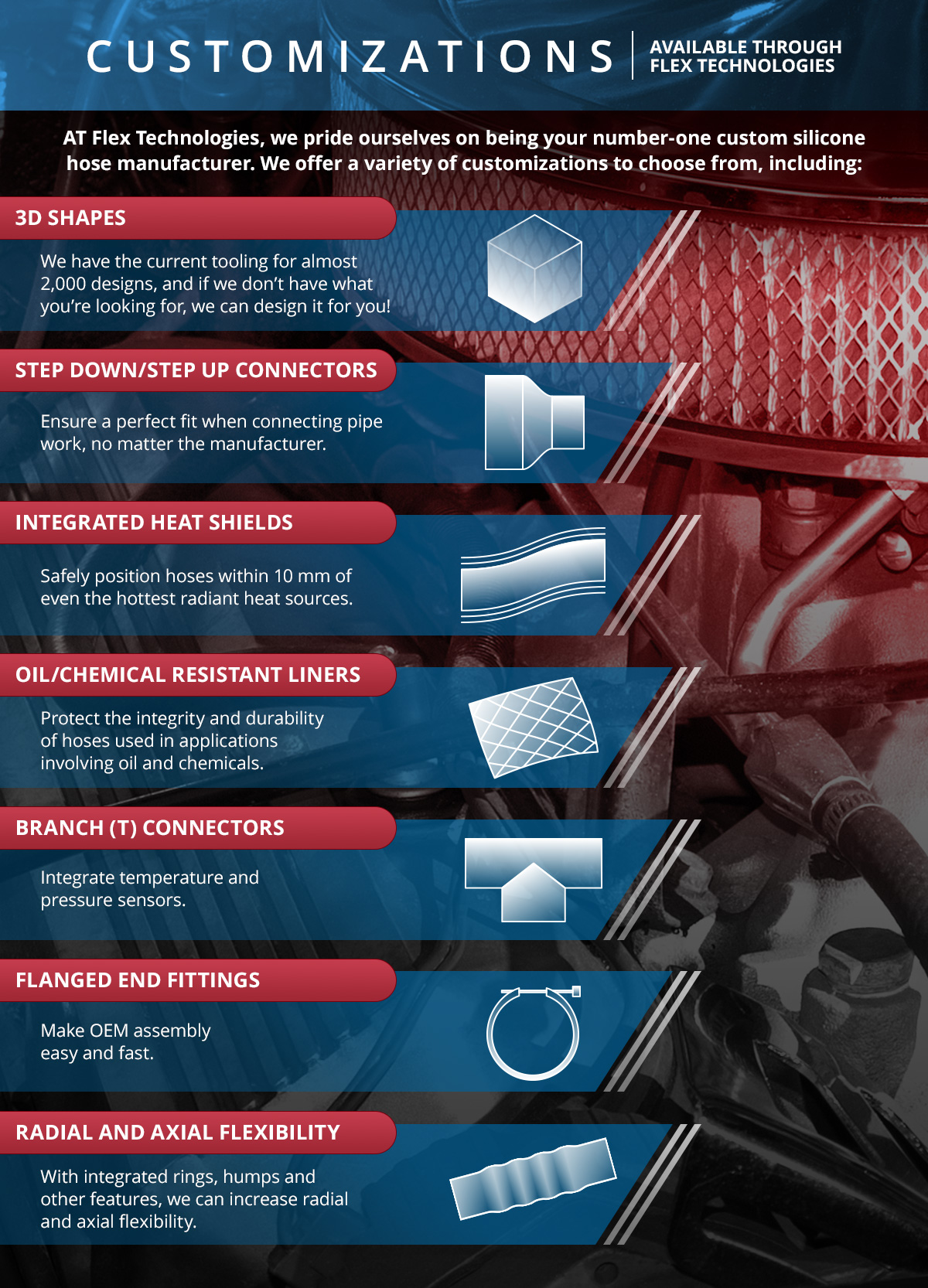

Flex Technologies offers a wide range of customization options that allow you to design a silicone hose that fits your exact needs while meeting OEM standards to ensure that everything fits and works properly. Those options include:

- Custom 3D Shapes

- Step Down/Step Up Connectors

- Integrated Heat Shields

- Oil and Chemical Resistant Liners

- Branch or “T” Connectors

- Flanged End Fittings (Integrated V Band Connections)

- Radial/Axial Location Features

- Controlled Axial Radial Flexibility

- Printed Clamp Position Guide Lines

Additionally, we have expanded our testing capabilities to include both in-house material and finished goods validation. Those new testing capabilities include:

![]()

In-House Raw Material Testing:

- Specific Gravity

- Hardness

- Coolant Immersion

- Oil Immersion

- Tensile Strength and Elongation

- Tensile Strength and Elongation at Break

- Tear Strength

- Modulus

In-House Finished Goods Testing:

- Heat Aging

- Coolant Immersion

- Oil Immersion

- Burst Testing (Fluid and Air)

- Dynamic Life Cycle Testing (Simulated Turbo and Cooling Systems)

- Adhesion

- Abrasion

- Bend Radius

- Radial Expansion

- Vacuum

- And Much More

We put our products through this testing to ensure their quality. You should have parts and equipment that you can depend upon, and when you order your custom silicone hoses from Flex Technologies, that is what you’re going to get.

After reading through those customization options, you might be wondering how they can specifically benefit you. This is a closer look at the OEM capabilities of our custom hoses.

Custom 3D Shapes

At Flex Technologies, we can produce any custom shape you can think of. We have current tooling for almost 2,000 custom hose designs, so we likely already have what you are looking for. However, if we do not, our in-house tooling and fabrication department can design custom tooling to meet or exceed every detail you have planned, quickly and effectively. The benefit of these shapes mostly come down to aesthetics, but if you’re a gearhead looking to make a statement when you pop your hood, this is a great way to do it.

Step Down/Step Up Connectors

These connectors make it easy to connect pipe work with different outside diameters to ensure a perfect fit, no matter who the manufacturer was. When you speak with our design team, we’ll be able to discuss exactly what type of connectors will work best for your needs.

Integrated Heat Shields

Custom integrated heat shields are permanently bonded to the hose, which allows for the hose to be positioned as close as 10mm from extremely radiant heat sources. This allows our flex hoses and tubes to be used in heat intensive situations that, without integrated heat shielding, silicone would not be able to handle. To learn more about the capabilities of our integrated heat shields, contact our Engineering department for details. We are happy to work with customers who need high-temp silicone hose solutions.

Oil/Chemical Resistant Liners

To ensure the integrity and durability of hoses and tubes that are in contact with oil or chemicals, fluorosilicone or fluorocarbon liners are a necessity. Both liners are available for all of our high-performance products. With exceptional oil and chemical resistance, these liners are great for industries such as automotive, marine, and aerospace.

Branch (T) Connectors

To integrate pressure or temperature sensors, branch connectors (also referred to as T connectors) are attached to coolant or air systems.

Flanged End Fittings

When you need silicone hoses that can handle extremely high pressures of turbo, or where a quick disconnect feature is needed, then flanged end fittings will be necessary. Also referred to as integrated V band connections, these “clampless” connections make OEM assembly much faster and easier to complete.

Radial and Axial Features

When it is necessary, we are able to place a small notch on the silicone hoses to your specifications to ensure accurate positioning with the mating tube. This will also make OEM assembly much faster.

Controlled Axial/Radial Flexibility

We are also able to integrate humps, rings, or other flexibility features to increase both axial and radial flexibility. This makes installation much easier, especially in cases where there are misaligned tube ends.

At Flex Technologies, we are committed to constantly pushing our manufacturing limits forward. When you’re looking for custom silicone hoses and tubes online, Flex Technologies is the company to call. We also offer wholesale opportunities for companies or individuals looking to become distributors or buy in bulk. To get more information regarding our custom design options, call us at your earliest convenience. Our incredibly friendly and knowledgeable team of representatives will be more than happy to answer any questions you may have about our products and how we can help you get the flexible silicone hoses and tubes you need.

Everything we do here at Flex Technologies revolves around silicone hoses and tubes. We are consistently working to make the highest quality, most durable hoses around that can be used for a wide variety of applications. To give you some ideas about where our custom silicone hoses and tubes can be used, we’ve gathered some of the different ways you can utilize them. We think you’ll find all of these applications can be improved with the use of our colorful, shiny, and durable silicone hoses.

Auto Detailing

As you walk down the aisles of a car show, you can see the incredible work that people have put into their vehicles. A quick pop of the hood shows the gorgeous interior, often a beautiful shine of chrome peeking through. With custom silicone hoses from Flex Technologies, you can add a splash of color that will stop people in their tracks when they see it. You’ll also have the added durability of silicone when you replace your standard OEM rubber hoses, which often break down under high-temperature, high-pressure conditions. Not only will this improve performance; it also gives you a chance to match the customization you’ve put into your car in every other area. Many car enthusiasts upgrade their vehicles with a full kit replacement from Flex Technologies. Speak with our engineering department to learn more about a full silicone hose kit for your car, truck, motorcycle, or any other vehicle you want to spruce up.

Home Brewing

Starting up a home brewery is becoming easier and easier as the hobby gains more popularity. Whether you buy a kit or put together your setup piece by piece, you’ll need a siphon hose to transfer your beer or wine from one container to another, without exposing it to much air. With a custom siphon hose, you can customize the fit to your exact equipment, while adding a cool splash of color to make your home brew setup look unique and cool.

Dairies

Even in situations where most people won’t see what our flex hoses can do, they can make a big impact. Silicone tubes are a key component in milking machines. The way milking machines work is by using a vacuum pump to create a pulsating suction that facilitates the most efficient flow of milk from the cow’s udder into the tank. Silicone tubing has a very high tolerance for working in a vacuum, which makes it the tubing of choice in milking. It operates as a connector between the vacuum pump and vacuum line, between the teat cups and the pulsator, and, in some cases, it also carries the milk into the tank.

Aquariums

For fish tanks with air devices, such as air stones or air-driven filters, tubing is necessary to connect them. While the standard for many years was vinyl tubing, it has a short lifespan and stiffens quickly. By using flexible silicone tubing instead, you get tubing that lasts longer, doesn’t get stiff as quickly, and is able to make a solid seal between the air device in an aquarium and the supply air posts. While it is a little more expensive than vinyl tubing, the increased lifespan means you won’t have to replace it nearly as often. Additionally, silicone tubing is able to provide better flexibility and withstand pressure better than vinyl.

Coffee Makers

Many coffee makers, cappuccino machines, and espresso machines utilize silicone tubing to great effect. Silicone is the right choice for these machines, thanks to its high heat resistance and protection from leaks. Depending on the model, these hoses may be used to transport the water within the machine. There are also models with milk reservoirs to automatically froth the milk, which use a silicone hose to do the job.

Manufacturing

Throughout many industries, flexible silicone hoses and tubes are used to complete a variety of manufacturing tasks. These industries include, but are not limited to, food, dairy, beverage, biotech, and pharmaceutical manufacturing. In just about every situation where tubing is needed, silicone hoses are a great option to transport products and liquid. However, unless they are coated with a fluorocarbon or fluorosilicone liner, there are some chemicals and liquids that silicone is not able to handle. Speak with our engineering team to see which chemicals and liquids are not recommended for silicone hoses.

Solutions For A Wide Range Of Applications

Flex Technologies will continue to push the envelope of what is possible, whether with silicone vacuum hoses, high-temp silicone hoses, custom coolant hoses, or other quality products. Our commitment to continuous improvement encompasses a great many things, including our equipment, processes, materials, facilities, training programs, and most importantly, our relationship with you, our valued customer.

Why choose Flex Tech silicone hoses? The reasons are many! We don’t just sell you a product and then vanish. We are available to answer your questions, even your most demanding technical inquiries. Our technical expertise enables our teams to truly be there for you with the high level of customer service you demand. We’re here to answer your questions, but that’s not all. Our technical teams will work side by side with you, every step of the way, for as long as you need our expertise.

This translates to custom solutions that work for you! It doesn’t matter if you order off-the-shelf parts from us or if you require fully customized parts that have never been made before. We’re here to work with you and meet your needs. It’s not about us; it’s all about providing great customer service so that you can access what you need for your systems and designs. We take silicone hose solutions seriously!

Our Commitment To Quality

We stand by our products and services, and we’re happy to work directly with you on customization solutions. Our flexible silicone hoses offer excellence in many categories, from being able to operate in harsh environments and temperature extremes, to resisting damage from the sun, ozone, radiation, and other environmental factors.

Please do not hesitate to contact us to learn more about our custom silicone hoses and tubes, how you can benefit from them, and how to become a wholesale distributor with Flex Technologies. As your industrial hose supplier, we sincerely look forward to working with you and providing you the quality silicone hoses and tubing that you need for your specific applications.

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar