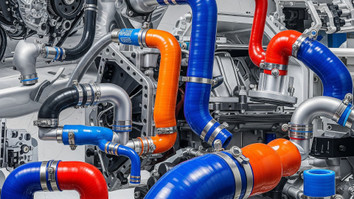

Step-by-Step Guide for Customizing Silicone Hoses for Specialized Applications

Posted by Flex Technologies on 7th Jul 2025

In today's advanced industrial, automotive, and aerospace sectors, off-the-shelf components often don’t make the cut. When you're deal

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar