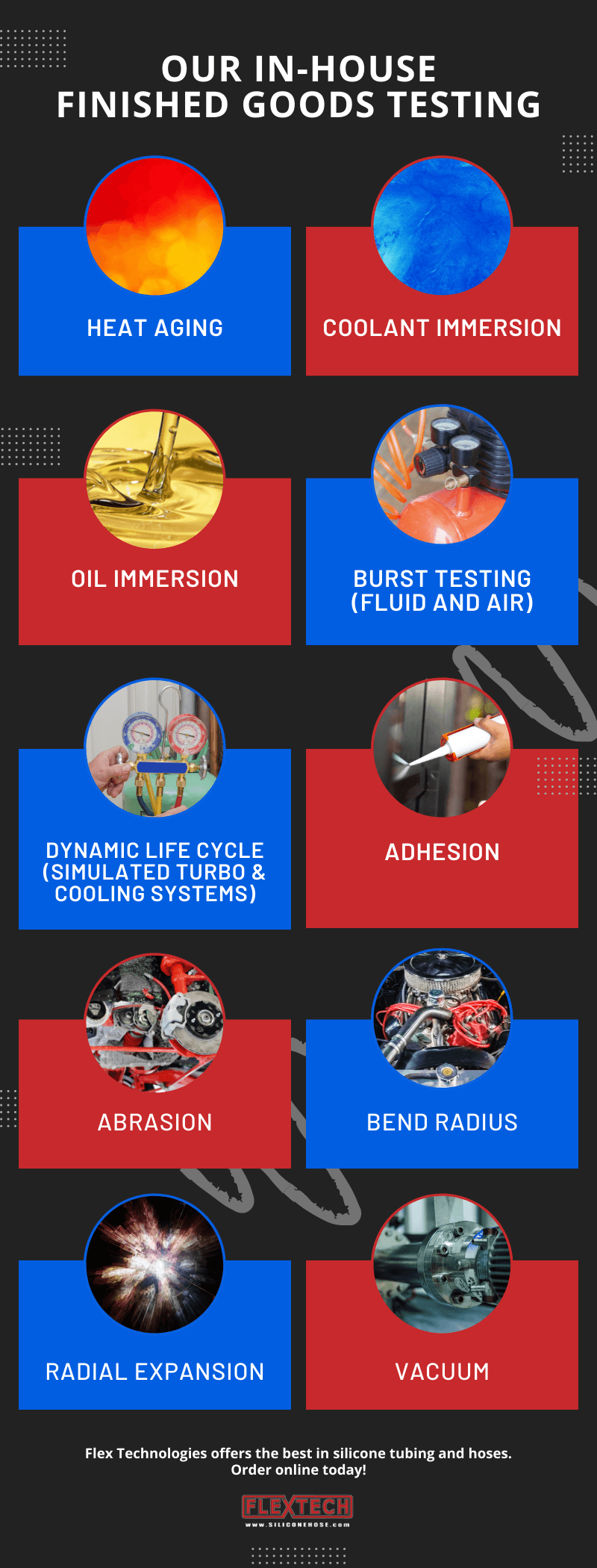

Here at Flex Technologies, we don't rest on our laurels. Our customers know us as the leading provider of silicone hoses and tubing. We've been ensuring our customers have exactly what they need with custom development and design services, too. We are always testing our products with the dual goal of ensuring that they work to their stated capabilities and so that we can continually improve our flexible silicone product offerings to you. Below, we'll take a look at our in-house finished goods testing process, so you can rest assured of the quality of silicone tubing and hoses you are receiving. Shop our selection today!

- Heat Aging. Heat aging is the process of determining the service temperatures for a product or material. It heats the product in order to accelerate the aging process and note the temperature at which the product begins to deteriorate.

- Coolant Immersion. This is the process of transferring heat from a hot substance in order to cool it down. We use this to test our finished silicone tubing and hoses, especially if it's perpetually exposed to these processes.

- Oil Immersion. Oil immersion is used to increase the resolving power of a microscope by immersing the lens and the specimen in a transparent oil. This is especially important to our medical equipment and tubing clients.

- Burst Testing (Fluid and Air). Burst testing is the process of using pressure to determine when a product will "burst" or fail. The pressure will be maintained for a given amount of time, and then the product will be inspected for damage. We use both fluid and air as the control medium to see how our flexible silicone tubing and hoses will hold up.

- Dynamic Life Cycle Testing (Simulated Turbo and Cooling Systems). Dynamic life cycle testing or assessments are used to test how substances will uphold to environmental conditions. This is done for both simulated turbo and cooling systems.

- Adhesion. Adhesion is a test to determine the attraction of two dissimilar particles to one another.

- Abrasion. An abrasion test looks for how materials hold up to the rubbing or friction of other materials against them. What will be noted is how fast the material (in our case, silicone tubes and hoses) will wear down, weaken, and/or splinter.

- Bend Radius. The bend radius is the smallest amount you can bend a tube, hose, or other material, such as a cable, without causing kinks or damage.

- Radial Expansion. Radial expansion is the measurement of what happens when more layers are added to a material, or, in our case, silicone tubing and hoses.

- Vacuum. A vacuum refers to an empty space devoid of matter. Here, the pressure is so low that no particles affect the process.

- And Others

PARTNER WITH FLEX TECHNOLOGIES TODAY

Flex Technologies is proud to be able to back up our leading silicone tubing and hoses with scientific data that proves the hardiness of our products. We want to ensure our customers that what we say about our leading silicone products is true. We are constantly seeking to improve our silicone products, and in-house testing of our finished goods allows us to see areas for improvement. In addition, our products adhere to the strict product quality standards of ISO 9001:2015 and IATF 16949:2016, giving you even more peace of mind when you decide to partner with us. We offer custom design and manufacturing of flexible silicone tubing and hoses with the goal of offering you high-performance silicone products you can depend on. To get started, contact us, or shop our selection today!

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar