Silicone hoses and rubber hoses are both widely used in various applications, but they have different characteristics and properties. Choosing the right type of hose for your application is critical to ensure optimal performance, safety, and longevity. Flex Technologies is a leader in silicone hose manufacturing for many industries, including pharmaceutical, food and beverage, and aerospace. In this blog post, we will discuss the differences between silicone hoses and rubber hoses to help you make an informed decision. Shop with us today!

![]()

Silicone Hoses

Durable Materials

Silicone hoses are made from high-quality silicone rubber, which is a synthetic material that exhibits excellent resistance to extreme temperatures, weathering, UV rays, ozone, and aging. Silicone hoses are also highly flexible, durable, and non-reactive to most chemicals and fluids. They are available in a wide range of diameters, lengths, colors, and reinforcements, including polyester, fiberglass, aramid, and wire.

Temperature Resistant

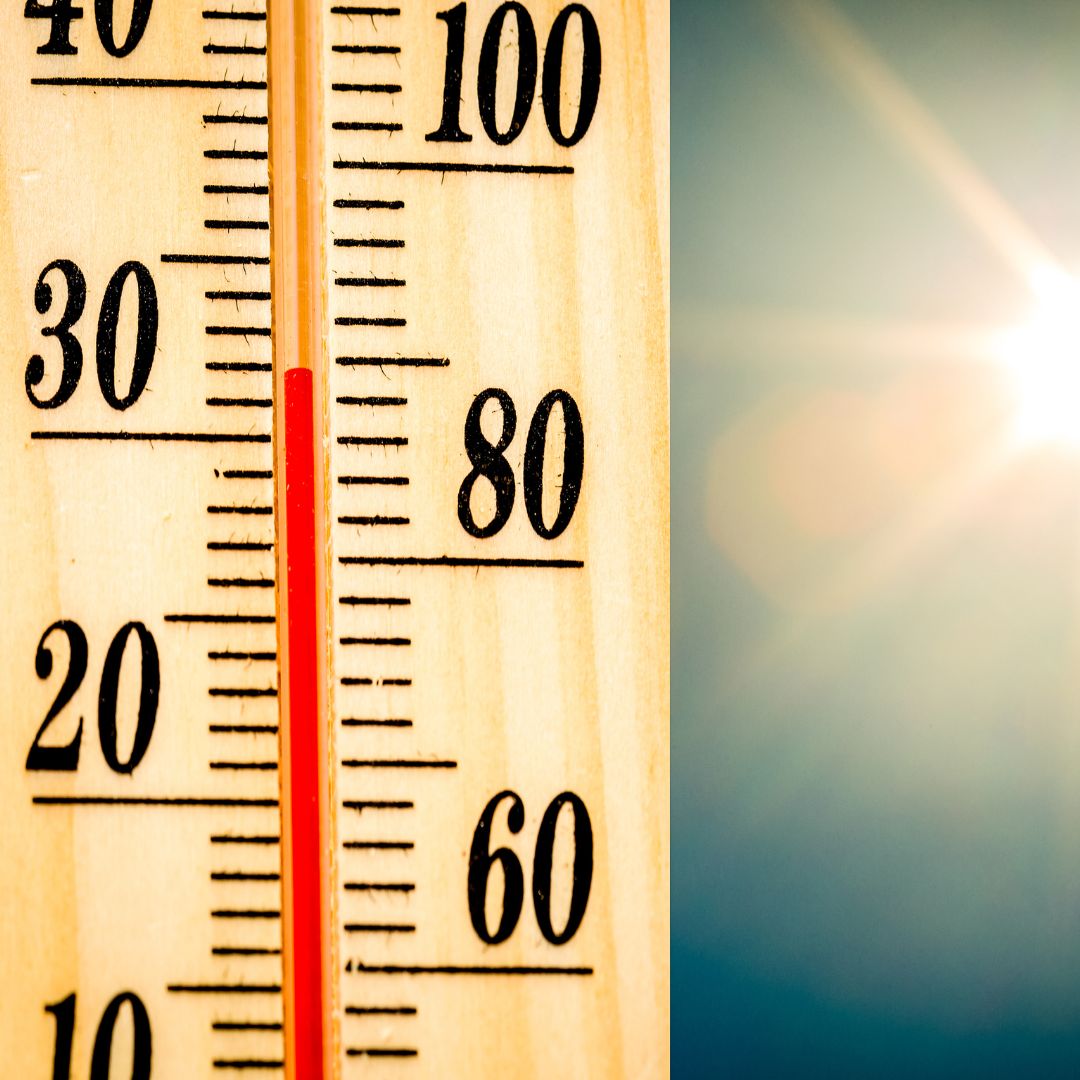

One of the most significant advantages of silicone hoses over rubber hoses is their temperature resistance. Silicone hoses can withstand extreme temperatures ranging from -65°C to 260°C, making them ideal for high-performance applications that involve exposure to heat, such as turbocharging, exhaust systems, and engine cooling. In contrast, rubber hoses are limited to a maximum temperature of around 120°C, beyond which they can become brittle, crack, or melt.

Insulation Properties

Silicone hoses also have excellent electrical insulation properties, making them suitable for use in electrical and electronic applications where high voltage and current are present. Moreover, silicone hoses are non-toxic and odorless, making them a preferred choice for food and medical-grade applications where hygiene and safety are critical.

Rubber Hoses

Flexible

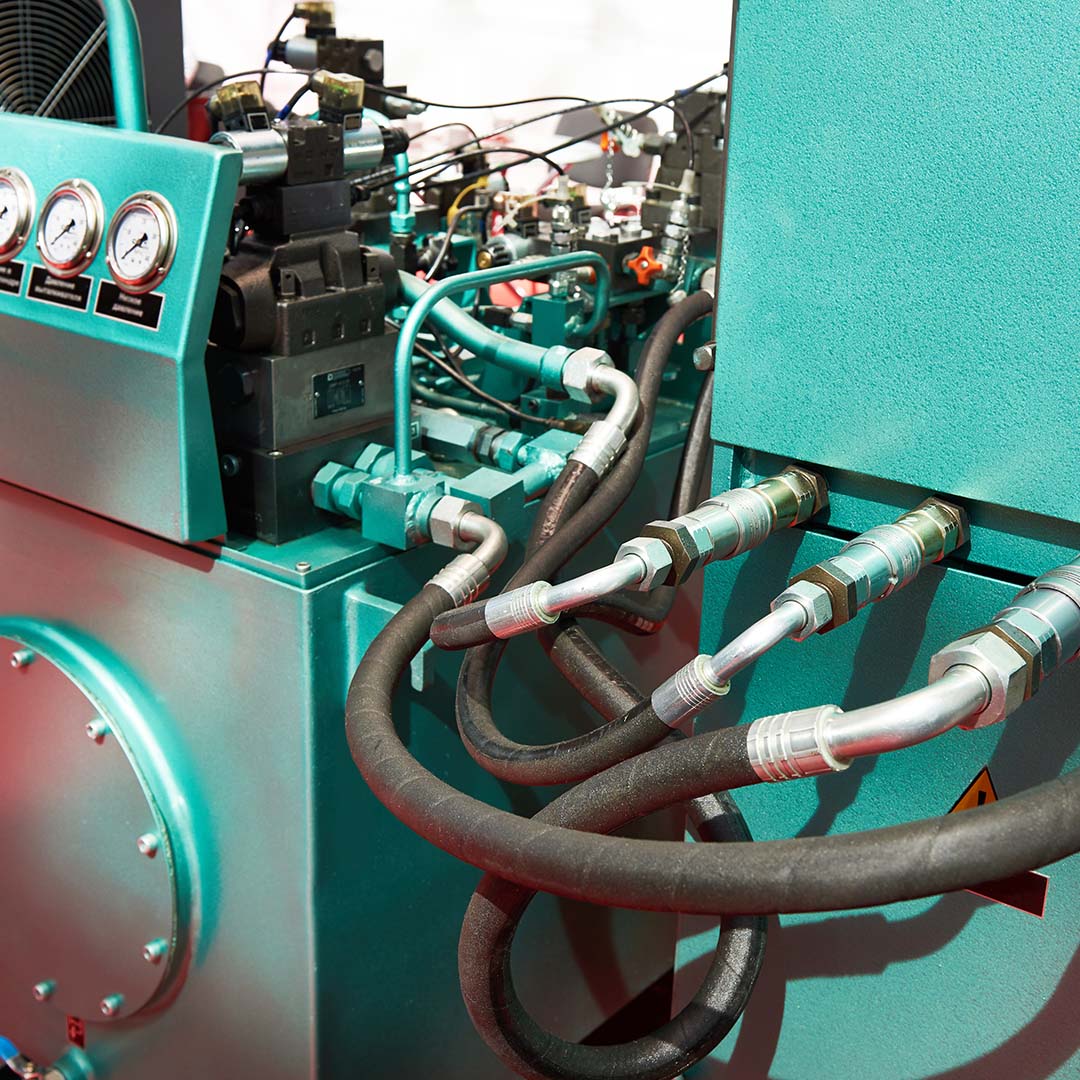

Rubber hoses are made from natural or synthetic rubber and are widely used in various applications, including automotive, industrial, marine, and construction. Rubber hoses are flexible, easy to install, and can withstand pressure and vibration. They also tend to be more affordable than silicone hoses, making them a popular choice for low-temperature applications that do not require high performance or durability.

Many Different Applications

Rubber hoses are available in different types, such as EPDM, Nitrile, Neoprene, and Butyl, each with its own properties and characteristics. For instance, EPDM rubber hoses are resistant to water, steam, and ozone, while Nitrile rubber hoses are resistant to oil, fuel, and grease. Neoprene rubber hoses are resistant to flames and chemicals, while Butyl rubber hoses are resistant to acids and halogens.

Poor Temperature Resistance and Can Degrade Easily

However, rubber hoses have some limitations compared to silicone hoses. Rubber hoses can deteriorate and degrade over time due to exposure to sunlight, heat, ozone, and chemicals, resulting in brittleness, cracking, and leakage. They also have poor temperature resistance and cannot withstand extreme temperatures without melting or deforming.

Which One is Better for Your Application?

The choice between silicone hoses and rubber hoses depends on several factors, such as temperature, pressure, chemical resistance, flexibility, and durability. If your application requires high performance, reliability, and temperature resistance, silicone hoses are the better choice. Examples of such applications include turbocharging, supercharging, exhaust systems, intercooler systems, and high-pressure water systems.

However, if your application involves low temperatures, low pressures, and mild chemicals, rubber hoses may suffice. Examples of such applications include ventilation, coolant systems, vacuum lines, and low-pressure water systems. Nevertheless, always ensure that you select the right type of rubber hose for your application, based on its chemical compatibility, temperature range, and lifespan. If in doubt, it's always best to choose a silicone hose from Flex Technologies in order to have a worry-free application.

SHOP TODAY

Both silicone hoses and rubber hoses have their unique advantages and limitations, and the choice between them depends on the specific application requirements. Silicone hoses are superior in terms of temperature resistance, electrical insulation, and chemical resistance, while rubber hoses are a more economical option for low-temperature and low-pressure applications. When in doubt, get in touch with our team. We can help you find the perfect silicone hose and tubing for your specific application. Contact us, or browse online today!

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar