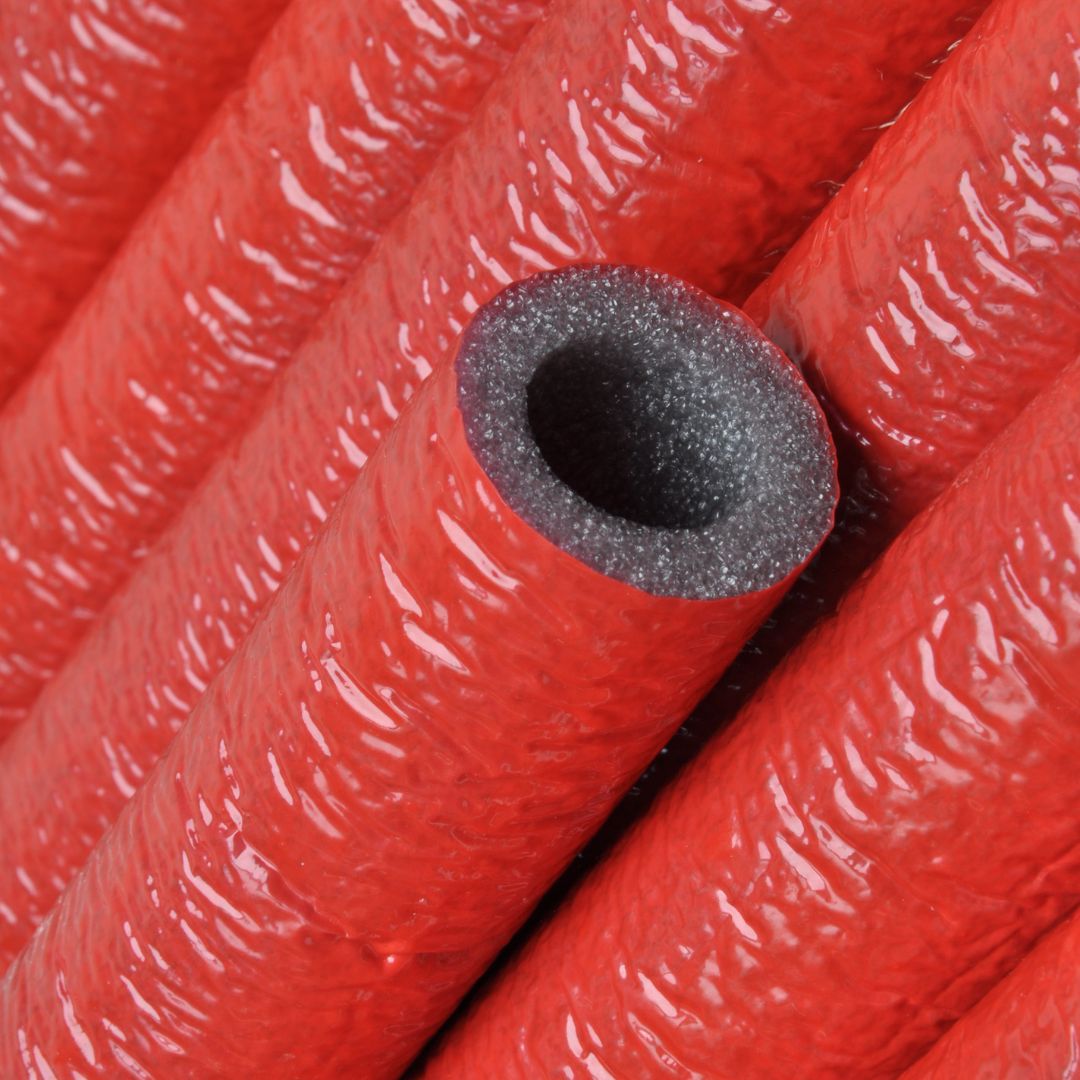

Silicone tubing is an essential component in many water-based applications, from pumping and filtering to heating and cooling systems. While different types of tubing materials are available, many businesses choose silicone tubing due to its excellent heat resistance, flexibility, and durability. Flex Technologies is a top-rated manufacturing company of silicone hoses and tubing that can be used for dozens of applications, including in the medical industry, biotech, automotive, aeronautical, food and beverage, and many more. In this article, we'll explore some important factors to consider when using silicone tubing in water applications and what you need to know to ensure the best performance and longevity of your tubing. Shop with us today!

Water and Resistance to High Temperatures

Silicone tubing is often used in water applications because of its excellent resistance to high temperatures. The material can withstand temperatures up to 500 degrees Fahrenheit, making it ideal for applications that involve hot water or steam. In addition, silicone tubing and hoses have a high degree of flexibility, which allows it to be easily bent or coiled without breaking. This feature makes it an ideal choice for use in systems with narrow or winding channels.

Effect of Minerals in Water and Silicone Tubing

One of the key considerations when using silicone tubing in water-based applications is the type of water being transported or processed. While silicone tubing is generally highly resistant to water, it can be susceptible to corrosion and damage in certain instances. For example, if the water contains high levels of chlorine or other chemicals, it may cause damage to the tubing over time. Similarly, if the water is too acidic or basic, this can also cause damage to the tubing.

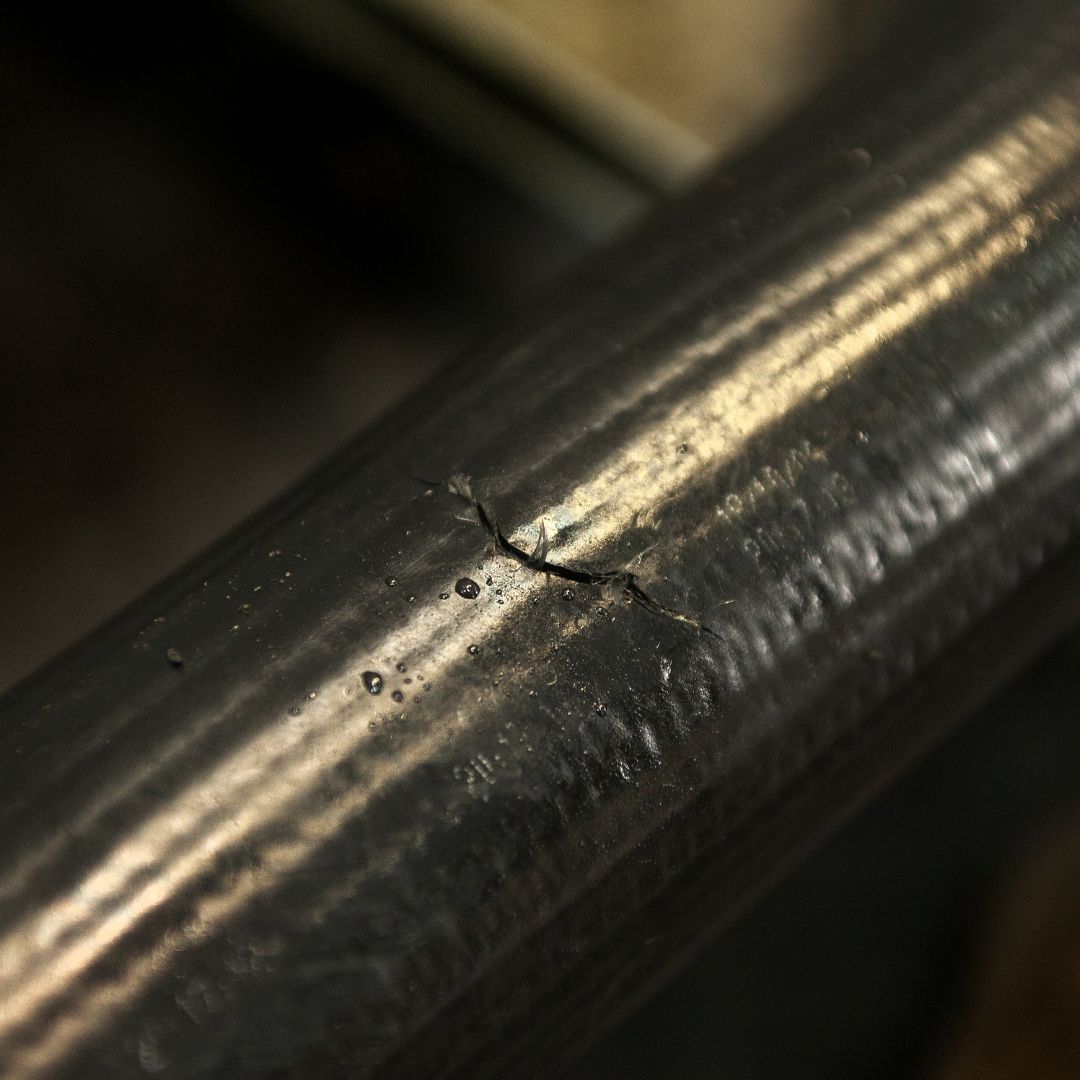

Effect of Cold Water on Silicone Tubing

Another important factor to consider is the temperature of the water being transported. While silicone tubing and hoses hold up great to high temperatures, the material may become damaged if it is exposed to very cold water. If the water temperature drops below freezing, the tubing may become brittle and crack, which can lead to leaks or other problems in the system.

Water Pressure

Another important factor to consider when using silicone tubing and hoses in water applications is the pressure of the water being transported. While silicone tubing is generally highly resistant to high pressures, certain types of tubing may perform better than others in specific high-pressure environments. For example, some types of tubing may be more suitable for use in hydraulic applications, while others may be better suited for use in low-pressure applications such as irrigation or sump pumps. It is essential to select the right type of tubing for your specific pressure requirements to ensure optimal performance and safety in your water-based system. Additionally, it’s important to choose silicone tubing with the proper thickness, as thinner tubing may be prone to bursting under high-pressure conditions. A professional supplier can help you determine the appropriate thickness for your particular application.

Different Types of Silicone Tubing

To ensure the best performance and longevity of your silicone tubing in water applications, it is important to select the right type of tubing for your specific needs. There are several different types of silicone tubing available, each with its own strengths and weaknesses. For example, some types of tubing are designed for high-pressure applications, while others are better suited for high-temperature environments. By selecting the correct type of silicone tubing for your application, you can ensure that it performs optimally and lasts as long as possible.

Proper Cleaning and Maintenance

Another important consideration when using silicone tubing in water applications is the need for proper cleaning and maintenance. Over time, debris, bacteria, and other contaminants can build up inside the silicone tubing and hoses, potentially leading to clogs or other problems in the system. It is essential to regularly clean and maintain the tubing to ensure that it remains free of blockages and other impediments. This may involve using specialized cleaning solutions or equipment, depending on the specific needs of your system.

The Best Supplier of Silicone Tubing

It is important to work with a reputable and experienced supplier such as Flex Technologies when selecting and installing silicone tubing and hoses in your water applications. A professional supplier will be able to help you select the right type of tubing for your needs, provide advice on installation and proper maintenance, and ensure that you have access to the necessary products and equipment to ensure optimal performance. By working with us as your trusted silicone tubing supplier, you can have peace of mind knowing that your water-based system is safe, reliable, and efficient.

LEARN MORE FROM FLEX TECHNOLOGIES TODAY

Silicone tubing is an excellent choice for use in water-based applications due to its excellent heat resistance, flexibility, and durability. However, it is important to carefully consider the specific needs of your system, including the type of water being transported and the temperature at which it is being transported. Working with a professional and experienced supplier such as Flex Technologies can help ensure that you select the right type of silicone tubing and hoses for your needs and that you are able to properly install and maintain it to ensure optimal performance and longevity. With the right care and maintenance, silicone tubing can be an essential component in your water-based system, providing reliable, efficient performance for years to come.

Our exceptional customer service representatives are here to help guide you on your silicone tubing and hose needs. We offer custom silicone tubing solutions, designing a tube to meet your specific applications. Shop online, or contact us to learn more today!

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar