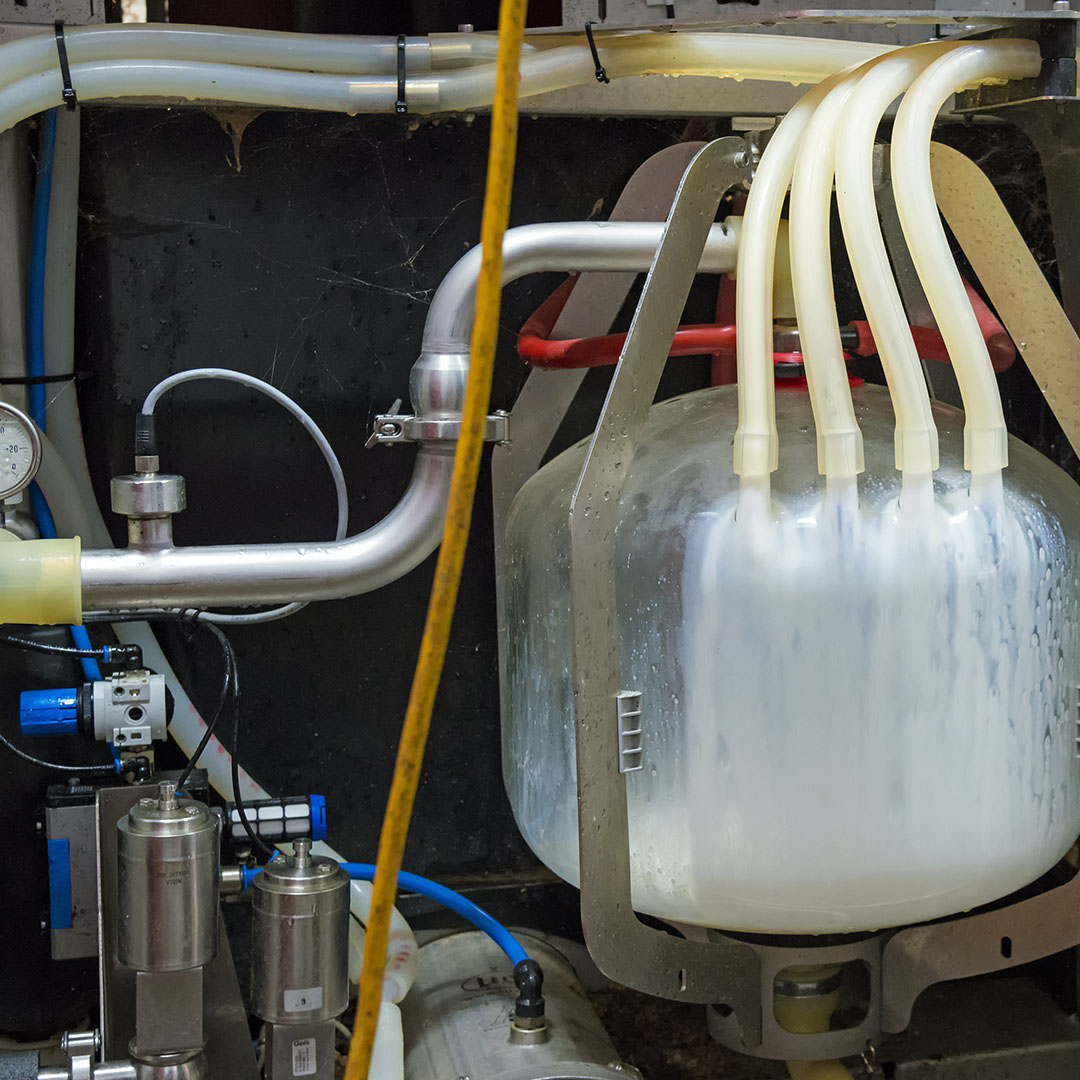

Silicone tubing plays an essential role in the dairy industry, serving as a key component in the equipment used for various processes involved in milk production and processing. The unique properties of silicone make it an ideal material choice for these applications. Flex Technologies is a leading provider of custom silicone hoses and tubing for many industries, including the dairy industry. Learn more below, and order from us today.

![]()

Offers Excellent Temperature Resistance

First and foremost, silicone tubing is known for its excellent temperature resistance. In dairy operations, high temperatures are often involved, such as during pasteurization and sterilization processes. Silicone tubing can withstand a wide range of temperatures, ensuring that it remains reliable and durable even under extreme conditions.

Flexible

Another important characteristic of silicone tubing is its flexibility. This allows it to navigate through complex systems and reach different parts of the machinery. The flexibility of silicone tubing also contributes to ease of installation and maintenance, reducing downtime and improving overall efficiency for your dairy operations.

Resistant to Microbes

Additionally, silicone tubing is highly resistant to chemical and microbial attacks commonly found in the dairy industry. It is non-reactive and does not absorb odors or flavors, ensuring the integrity and quality of the dairy products throughout the production cycle. This resistance to chemicals and microbes of our custom silicone hoses and tubing also helps in maintaining a sanitary environment, which is crucial in the dairy industry to prevent contamination and ensure food safety.

Contains Sealing Properties

Silicone tubing from Flex Technologies is also known for its excellent sealing properties. It can provide a tight and secure connection between different components, preventing any leaks or contamination. This is especially important in processes such as milk transfer or CIP (cleaning-in-place) operations, where maintaining a hygienic environment is critical for consumer safety and for government regulations

Easy Maintenance

Furthermore, silicone tubing is easy to clean and maintain. Its smooth surface prevents the buildup of dirt, residue, or bacterial growth, making it easier to sterilize and ensuring a higher level of hygiene. This ease of cleaning helps to streamline operations, save time, and reduce the risk of cross-contamination of your dairy products.

ORDER TODAY

Silicone tubing plays a vital role in the dairy industry by ensuring the smooth and efficient operation of various equipment used in milk production and processing. Its temperature resistance, flexibility, chemical resistance, sealing properties, and ease of cleaning make it an ideal choice for these applications. By using silicone tubing, dairy companies can improve productivity, maintain product quality, and ensure food safety standards are met. Order custom silicone tubing online today.

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar