![]()

Silicone hoses offer numerous uses in so many different settings, from industrial to a consumer’s daily life. You’ll find quality silicone hoses inside a factory, in your car engine, in home brewing systems, in hospitals, in airplane engines, and in countless other places for a wide range of applications.

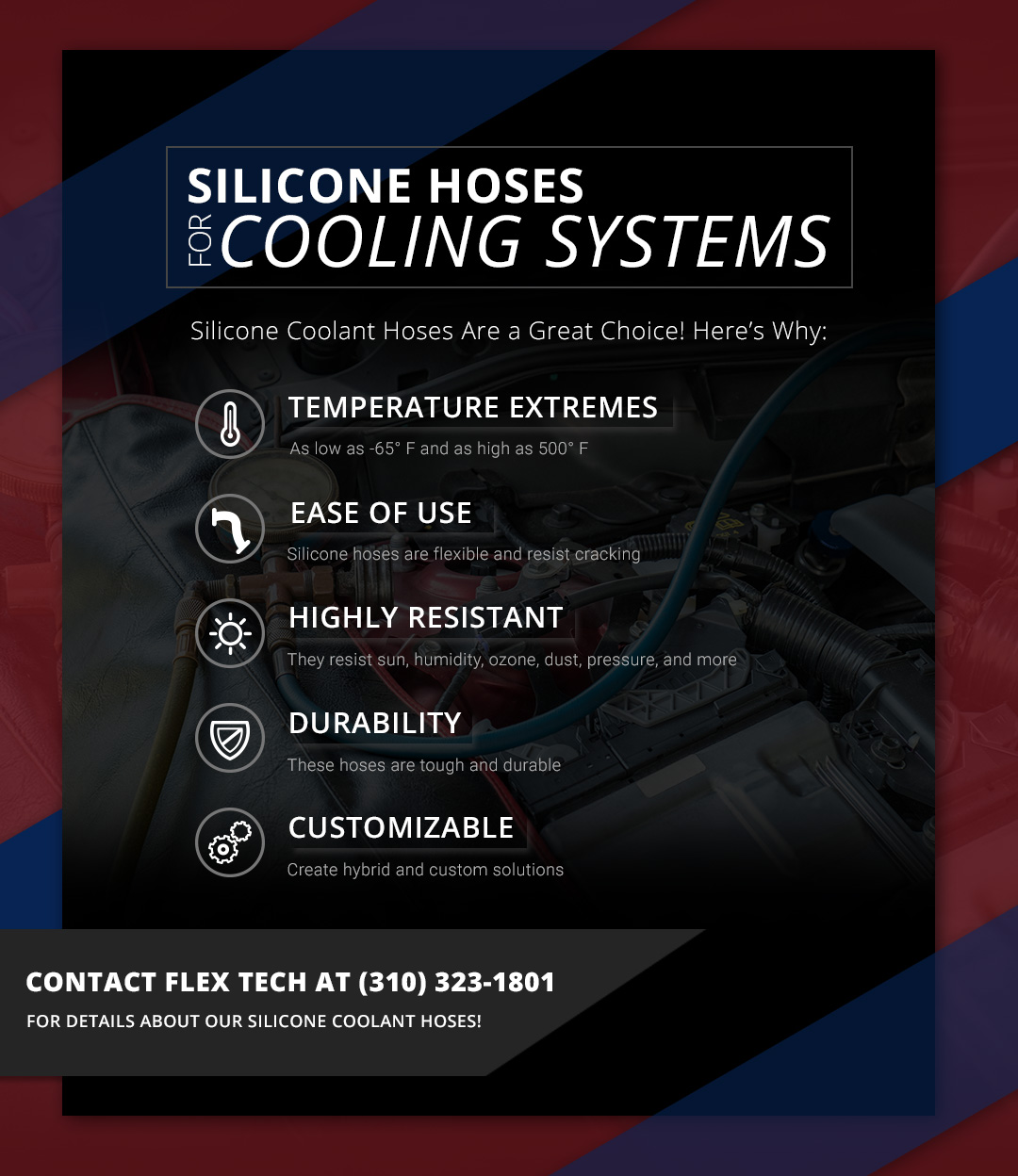

In today’s blog, we want to focus on silicone coolant hoses used in refrigeration and cooling systems. Whether you’re looking for a convenient way to transport fluids in low-temperature environments, or you want hoses that will keep contents cool in a hot environment, silicone offers numerous benefits.

Wide Operating Temperature Ranges

Standard hoses work well in temperatures as low as -65 degrees Fahrenheit and as high as 350 degrees Fahrenheit, and there are premium hoses that function without degrading at temperatures as high as 500 degrees Fahrenheit.

These are wide temperature ranges, which makes silicone the material of choice for extreme conditions. For example, if you need tubing that keeps the contents inside cool even when the outside is exposed to very high temperatures, silicone is a great choice.

The reverse is also true; in cold, refrigerated environments, silicone hoses can keep contents flowing easily without freezing even when external temperatures are low.

Easy to Install and Build With

In addition, silicone hoses are flexible enough to bend without cracking, making it easy to incorporate them into installations. They can be combined with other materials, including metal clamps and connectors, for hybrid solutions that meet cooling system requirements. What’s more, they come in different sizes, making it easy to fit them into small, tight spaces.

Resistant to Environmental Factors

Silicone offers resistance to a number of factors that may significantly degrade or compromise other materials. These are some of the qualities silicone hoses are known for:

- Handle high and low temperatures

- Are resistant to hardening or cracking

- Tolerate sunlight and ozone well

- Operate well in moist, steamy, and foggy conditions

- Resist dust

- Handle a wide range of pressures

- Insulate against electricity

- Resist a number of chemicals without degrading

Because silicone hoses for coolant and refrigeration applications are resistant to so many different environmental factors, they are incorporated into designs that need to hold up well in extremes. They perform well whether used outdoors or indoors.

Remain Flexible, Even in Harsh Conditions

One of the great things about silicone coolant hoses is how flexible they remain, even in harsh conditions like a car engine where temperatures escalate and hot oil flows through tubing to keep metal parts lubricated. Some materials harden or crack under these conditions, but not silicone.

Silicone Hoses Are Long-lasting

Especially when compared to rubber hoses, silicone is durable. This means that the system you’re designing should remain in operation significantly longer before you have to replace any parts. Whether it’s an engine, an industrial transport system, or a food processing plant, the fewer parts replacements that you have to make, the better.

Bring Us Your Questions!

Do you need fluid transport solutions for any refrigeration or cooling system applications? Turn to Flex Tech. We have the products and the expertise you need. We’ve been supplying customers with quality silicone hose products since 2003, and our technical team regularly creates custom solutions for our clients from their drawings, diagrams, and specifications.

We are ready to work with you to help you find the ideal off-the-shelf parts for your design, or to develop a fully customized plan to meet your unique needs. For quality parts and outstanding technical assistance, get in touch with Flex Technologies today!

![]()

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar