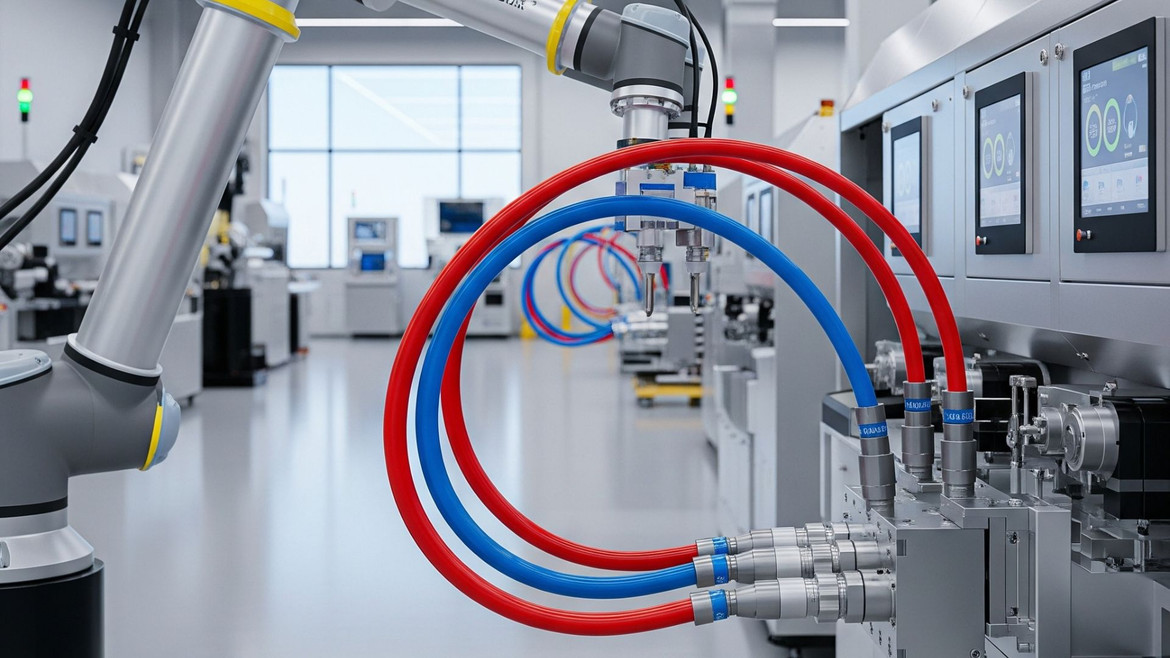

In the world of industrial manufacturing, the pursuit of efficiency is relentless. Every component, no matter how small, is scrutinized for its ability to enhance output, reduce costs, and minimize downtime. While massive robotic arms and complex control systems often steal the spotlight, the humble hoses that transport critical fluids, gases, and materials are the unsung heroes of a productive operation. When you choose inferior manufacturing hoses, you are introducing a weak link that can lead to catastrophic failures and costly interruptions.

At Flex Technologies, we’ve seen firsthand how upgrading to advanced polymer solutions, specifically high-quality silicone hoses, can revolutionize a facility's productivity. Here are six key ways that incorporating silicone into your processes can have a significant and positive impact on your bottom line. Shop today.

![]()

Drastically Reduced Downtime from Superior Durability

The most significant drain on productivity is unscheduled downtime. Traditional rubber or plastic hoses are susceptible to cracking, hardening, and failing under the constant stress of industrial environments. Our silicone hoses are engineered for longevity, resisting the effects of ozone, UV radiation, and daily wear and tear far better than their counterparts. This inherent durability means fewer replacements, fewer leaks, and more time spent in production.

![]()

Uninterrupted Operation with High-Temperature Resistance

Many manufacturing processes involve extreme temperatures that would cause standard hoses to melt or degrade in an instant. A high temperature silicone hose is specifically designed to perform flawlessly in these harsh conditions, often withstanding continuous temperatures of 350°F and higher. This reliability ensures that processes involving hot liquids, steam, or forced air induction can run continuously without the risk of hose failure, keeping your production schedule on track.

![]()

Enhanced Flow and Purity with Smooth Interiors

The efficiency of your system depends on the smooth, uninterrupted flow of materials. The interior surface of our silicone tubing is exceptionally smooth, which minimizes friction and prevents the buildup of deposits that can lead to clogs or contamination. In industries like food and beverage or pharmaceuticals, this quality is critical for maintaining product purity and ensuring consistent flow rates, directly impacting product quality and production speed.

![]()

Perfect Integration with Custom Solutions

Off-the-shelf components rarely provide a perfect fit for complex, modern machinery. This is where custom silicone hoses become a game-changer. We can engineer hoses to your exact specifications, including precise angles, diameters, and lengths. This eliminates the need for awkward adapters or inefficient routing, ensuring optimal flow and a perfect fit that reduces stress points and potential failure sites. Properly designed manufacturing hoses are essential for a truly optimized system.

![]()

Versatility Across Demanding Applications

The chemical inertness of silicone makes it an incredibly versatile material. It can handle a wide range of fluids and chemicals without degrading or leaching harmful substances. This makes our specialized silicone hoses and tubing the ideal choice for a vast array of industries. From coolant lines in automotive manufacturing to transfer lines in biopharmaceutical labs, the right high temperature silicone hose can improve process stability and product integrity.

![]()

A Safer and More Reliable Workplace

Ultimately, a productive facility is a safe one. The reliability and strength of our specialized silicone hoses and tubing with OEM capabilities mean fewer unexpected bursts, leaks, or failures that could endanger employees or damage expensive equipment. When your team can trust the components they work with, like our custom silicone hoses, they can operate with greater confidence and efficiency.

![]()

GET STARTED TODAY

The impact of high-quality components on your overall productivity cannot be overstated. By upgrading from standard hoses to superior silicone tubing and hoses, you are making a direct investment in reducing downtime, enhancing safety, and improving the efficiency of your entire operation. Contact Flex Technologies today to learn how our advanced solutions can become the unseen engine that drives your business forward.

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar