![]()

Silicone hoses are flexible parts that can meet the system requirements of many industries, including automotive, pharmaceuticals, water purification, food processing, and cosmetics, among others. A wide range of parts exist, though, which makes it essential that you know what your requirements are before ordering to ensure you’ll receive the right products. Here are several points to consider when you’re ready to place your order for silicone hose tubing.

What Are You Building?

What type of fluid transportation system are you building? What type of environment will this system be operating in? How large will your complete processing system be? Will it need to be expanded in the future?

The more you can answer about your design now, the better it will meet your needs after you’ve built it. Fluid transportation systems that use silicone hoses can be compact, like the engine of your car, or enormous, like a food processing plant. In both large and small system designs, you need to consider temperature and pressure requirements, how strong and durable the hose parts are, how flexible they are (this is especially important when your design requires bends and turns), and how stable and inert the tubing material needs to be (to maintain the purity and quality of the fluid passing through the hoses).

There’s a lot to think about, so design carefully, and get technical help if you need it.

What Industry Specifications Need To Be Met?

Every industry has different specifications and requirements that must be met. Learn what the requirements are for your particular industry. Contact regulation agencies to find out what they require. When it’s time to order silicone hoses, check with the manufacturer to see which tubing parts meet the specifications of your industry.

As you can imagine, industry requirements for a facility that makes liquid cough medicine, for example, will differ greatly from specifications for tubes that transport coolant in a car engine. Don’t assume that any part will do; first learn the industry requirements for your specific application, and then order the correct parts.

What’s Your Budget?

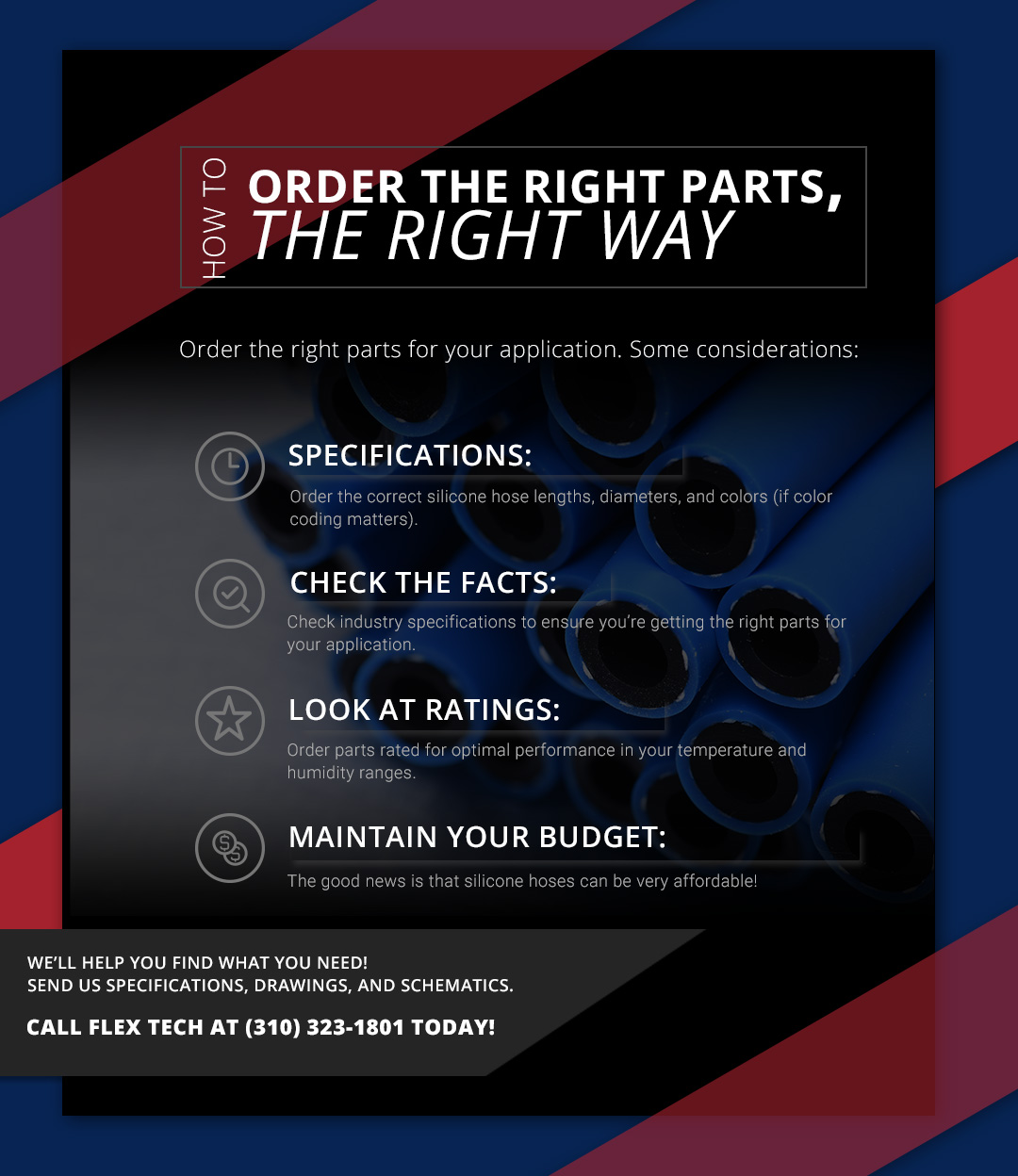

For most businesses, including nonprofits, costs matter! Figure out what your budget is, then price around. While different materials may meet your design needs, not all of them will be cost-effective. Balance your system requirements with your business budget to find the ideal solution.

What Criteria Need To Be Met?

We’ve talked about industry specifications, but there are many other criteria that need to be met. Here are some things to consider:

We’ve talked about industry specifications, but there are many other criteria that need to be met. Here are some things to consider:

- The length(s) of tubing needed

- The tubes’ diameters

- Temperature requirements (especially for extreme highs or lows)

- Humidity levels that can be tolerated

- Purity levels of the material

- Parameters such as strength, durability, flexibility, and connectivity

- Compatibility with other parts, especially for custom or hybrid systems

- Color coding, if needed

- Type of liners needed, if any

These are just some of the considerations you need to think about before ordering parts. There are others, and their importance will vary from design to design, and from one industry to the next.

Are Your Instructions Clear?

When you place your order, you will need to select the right types of hoses and the right sizes, and you’ll likely need to include special instructions. The clearer and more detailed that your instructions are, the greater your chances of receiving parts that meet your expectations and design goals.

Double-check and triple-check your instructions before sending them off. Have a second or third pair of eyes look over your order and your special instructions (which ideally, will include CAD drawings or PDF files with design details) before sending them off.

Have You Ordered The Right Sizes?

We can’t emphasize this enough! Silicone hoses come in many different lengths and diameters. Be sure you order the right sizes. Double-check your design specifications, and double-check your order, to avoid unpleasant surprises when your shipment arrives.

When You Need Help

Flex Technologies has been a valued industry supplier of silicone hoses since 2003. We have the technology and expertise to assist our clients with a variety of design considerations. We regularly create custom solutions that meet industry specifications; if you need help with your design or your order, rest assured that technical assistance is just a phone call away. Reach out today!

Default Currency

Default Currency

Mexican Pesos

Mexican Pesos

Canadian Dollar

Canadian Dollar